Breaking down the microbiology world one bite at a time

Self-healing ‘leather’

Imagine a material that can grow, adapt, and heal itself, just like a living organism. That’s the goal of a new field of research called Engineered Living Materials (ELMs). ELMs are made of living cells that are designed and shaped in a lab to create novel materials with amazing properties. Unlike conventional materials like wood or metal, ELMs can sense and respond to their environment, and even fix themselves if they break.

Some ELMs are hybrid living materials, which combine man-made materials with living cells that act as smart sensors or activators. For instance, some scientists have found a way to use bacteria to heal cracks in concrete. They embed the bacteria in the concrete, staying dormant until the concrete cracks. Then, the bacteria wake up and produce a glue-like substance that seals the crack. This way, the concrete can self-repair without human intervention.

But what if we could make a material that is entirely living, without any artificial parts? That’s where fungi come in. Fungi are amazing organisms that can produce strong, water-resistant, and self-healing materials. You may have seen some examples of fungal materials in products like mushroom leather or mycelium furniture. Or you can read about their possible application in electronics here or their use as air-conditioners here.

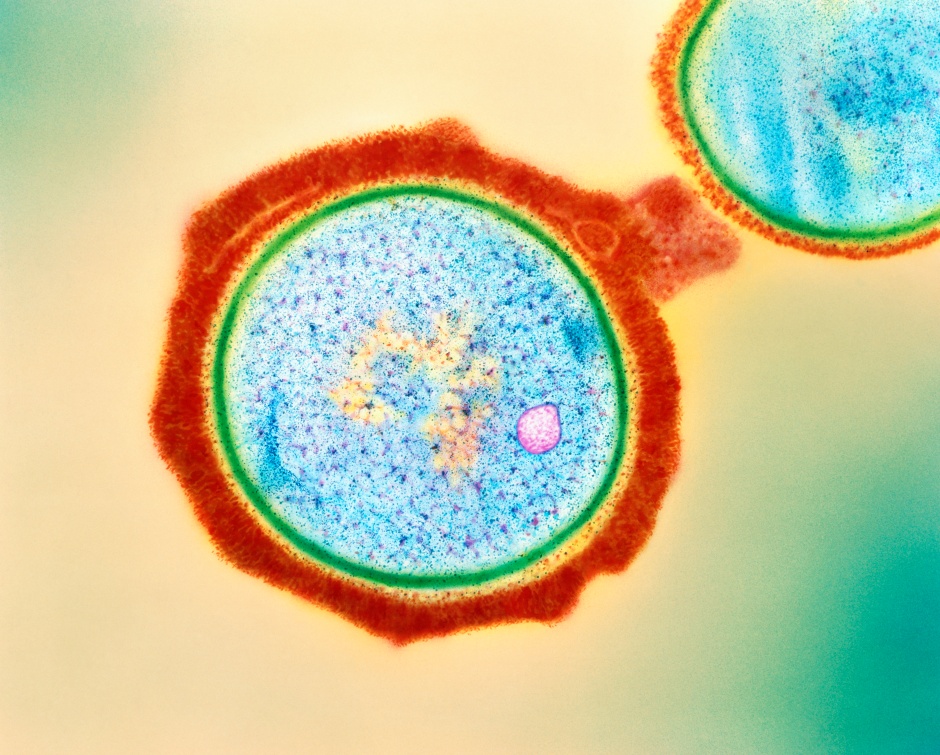

Recently, a team of researchers tried to create a new kind of fungal material that can heal itself autonomously. They used Ganoderma lucidum, a fungus usually found on decaying hardwood trees that has natural self-healing abilities. They wanted to make a material that could be used for things like furniture, car seats, or fashion items, and that could repair itself if damaged.

What makes the fungus heal itself?

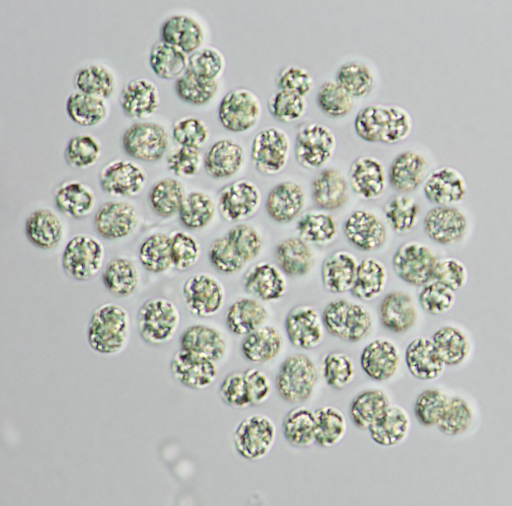

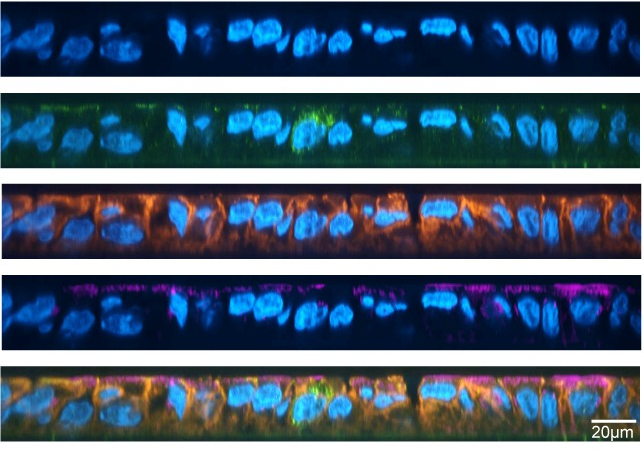

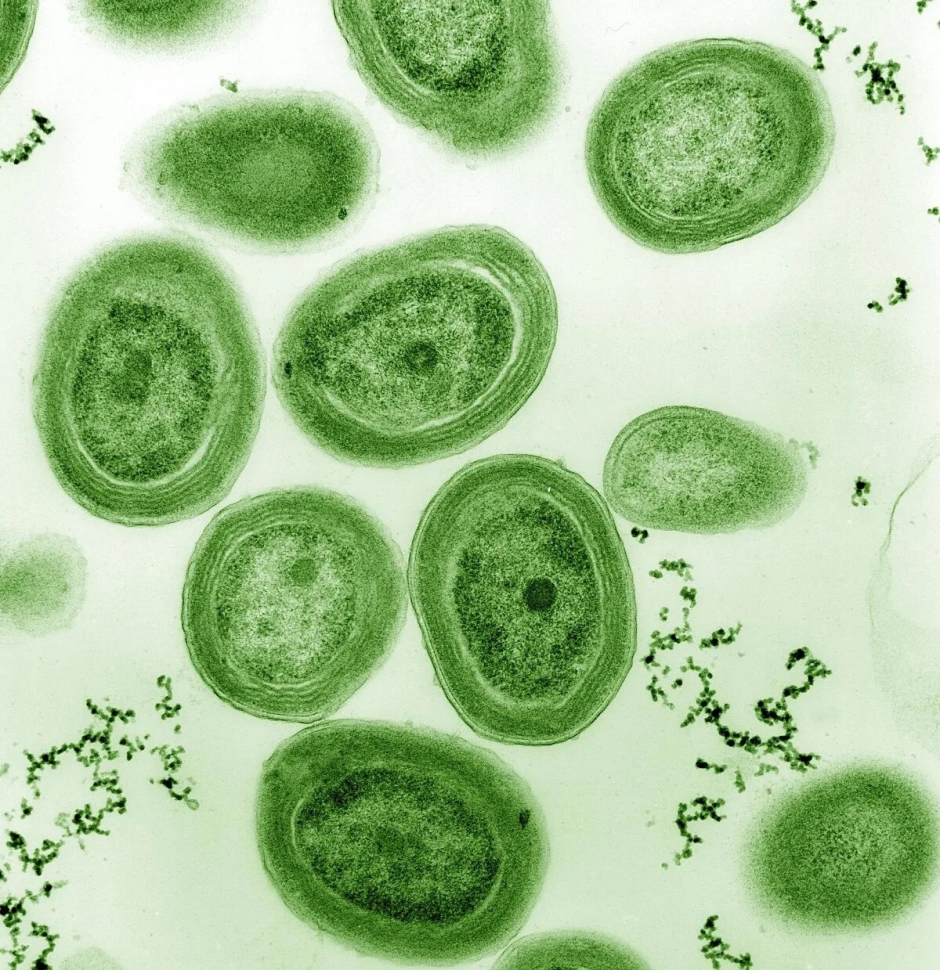

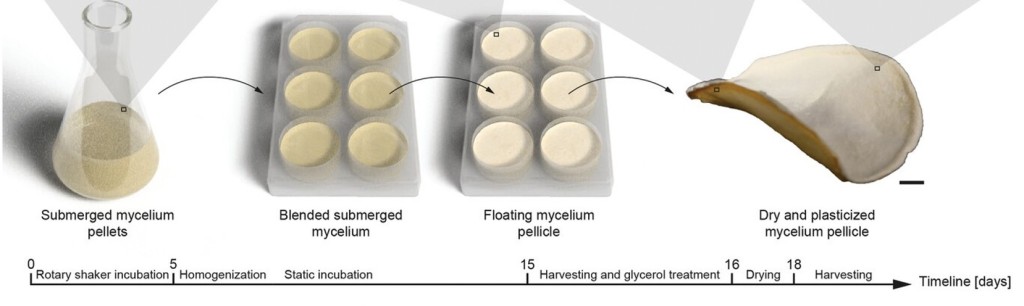

To get the fungus to look and feel like leather, the mycelium (the thread-like parts of a fungus) was grown in liquid and subsequently grown in containers. This results in a so-called ‘skin’. To test if the skin was self-healing, they dried it and checked if it was able to revive. The researchers tested different kinds of fungi, including some that are also commonly used to make mycelium materials such as Ganoderma resinaceum, Trametes versicolor, and Pleurotus ostreatus. All fungi except the last one were able to revive, due to their (higher) chlamydospore production. A chlamydospore is a protective fungal structure aiding survival and dispersal, like a resilient seed for fungi.

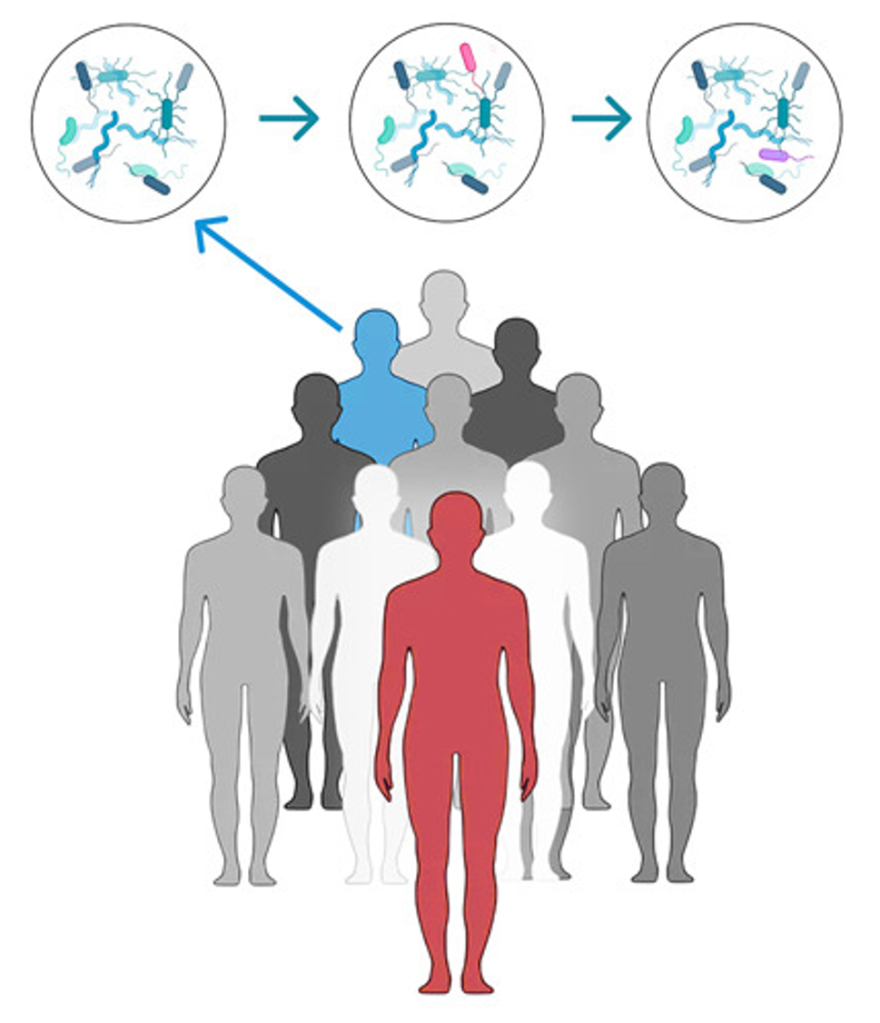

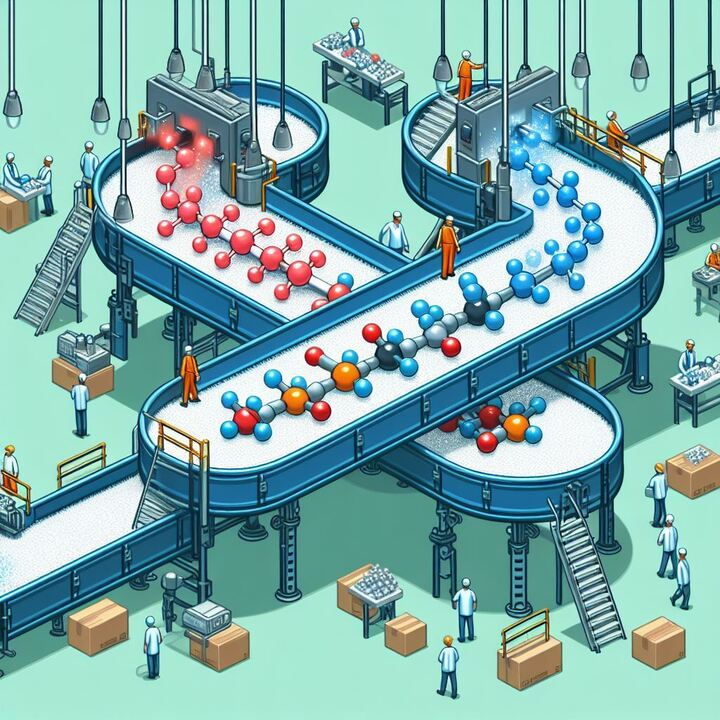

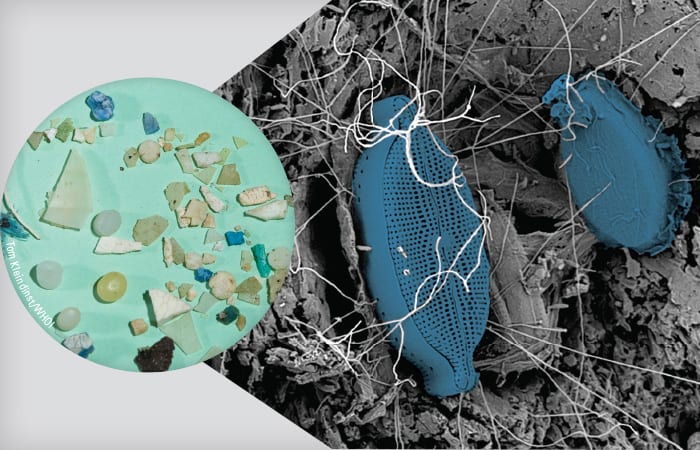

The liquid-grown mycelium is blended, and grown in a container. The skins are harvested, plasticized and dried to end up with mycelial skin. Adapted from the original article

How well and how fast can the material recover from damage?

After showing that the skins were able to revive, the researchers tested how the healing process could be optimised. They punched holes in the skin and tried different techniques to try and fill in the gap. In the end, the best way to heal the holes was to soak the mycelium in a nutrient-rich liquid or place it on a nutrient-rich solid. Even holes up to 10mm in diameter could be healed this way after two days! And not only that, when the material was torn in two, the two halves were connected again and after 4 days there was no sign of any damage anymore.

Can the material become stronger after healing itself from damage?

The researchers found that mycelium became twice as strong after healing for 3, 5, or 10 days, compared to before healing. This is because the mycelium grew new biomass inside and on top of the old one, making it thicker and denser. They also found that the healed mycelium was as strong as the undamaged one, and could resist the same amount of stress. However, the healed mycelium was slightly less stretchy and more stiff than the undamaged one. This could be because of the different structures of the new and old biomass. The researchers also found that mycelium that healed for 5 days had the best quality because it did not break in the damaged area and did not form unwanted growths, unlike the ones that healed for 3 or 10 days. Another interesting property they found was that the healed material became more water-resistant due to the new mycelium forming on top of the old one.

Will we see this material on the market soon?

Sadly, some more research is needed to incorporate this material into usable products. For instance, it is not sure if the material can survive harsher conditions such as chemicals or washing cycles that could occur using it as a leather substitute. And maybe more importantly, it is not yet known if the mycelium could heal itself multiple times. Unlike most other living materials, this fungal material does not rely on genetic engineering or co-cultivation, but on physical manipulation and environmental response. This makes it a unique and versatile material for sustainable and resilient applications, such as furniture, automotive seats, and fashionwear. This study also opens the possibility of developing a new generation of living materials that could become even more “living” and dynamic, by programming complex behaviours such as environmental sensing, morphological changes, or cellular reorganization over time.

Link to the original post: Elise Elsacker, Meng Zhang, Martyn Dade-Robertson. Fungal Engineered Living Materials: The Viability of Pure Mycelium Materials with Self-Healing Functionalities. Advanced Functional Materials, April 2023. https://onlinelibrary.wiley.com/doi/10.1002/adfm.202301875

Featured image: Created with Bing image creator