Breaking down the microbiology world one bite at a time

Microbial Marvels: Rescuing Earth One Dye At A Time

When you eat anything, what are the things you notice? smell and appearance of the food, including its color. In this article, we will dive in to understand how microbes can be utilized to produce food coloring, a crucial aspect of any food or beverage as it informs us about their quality, freshness, and flavor. Studies have shown that synthetic food colorant may cause allergic reactions. Red colorant is a widely used colorant seen in many food and drink products including Rice Krispies or Mountain Dew Code Red. Therefore, there exists a huge demand for natural food colorant.

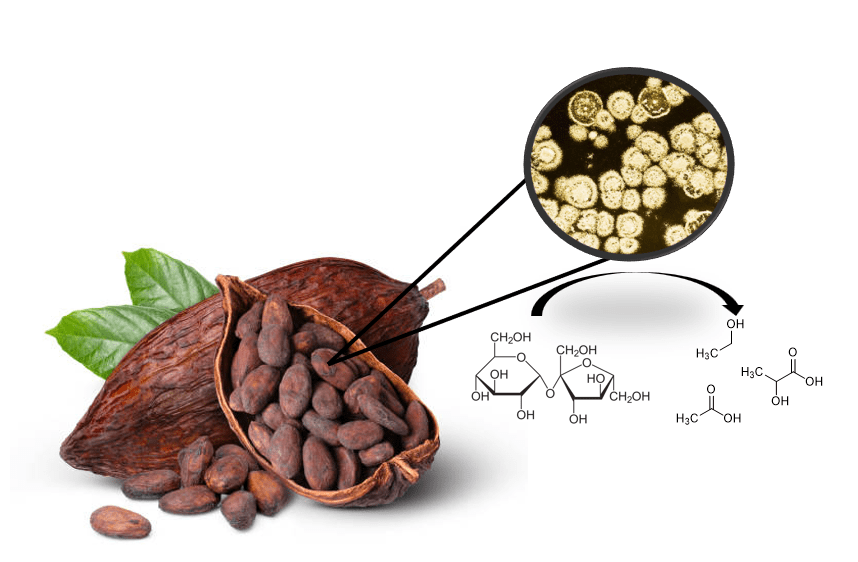

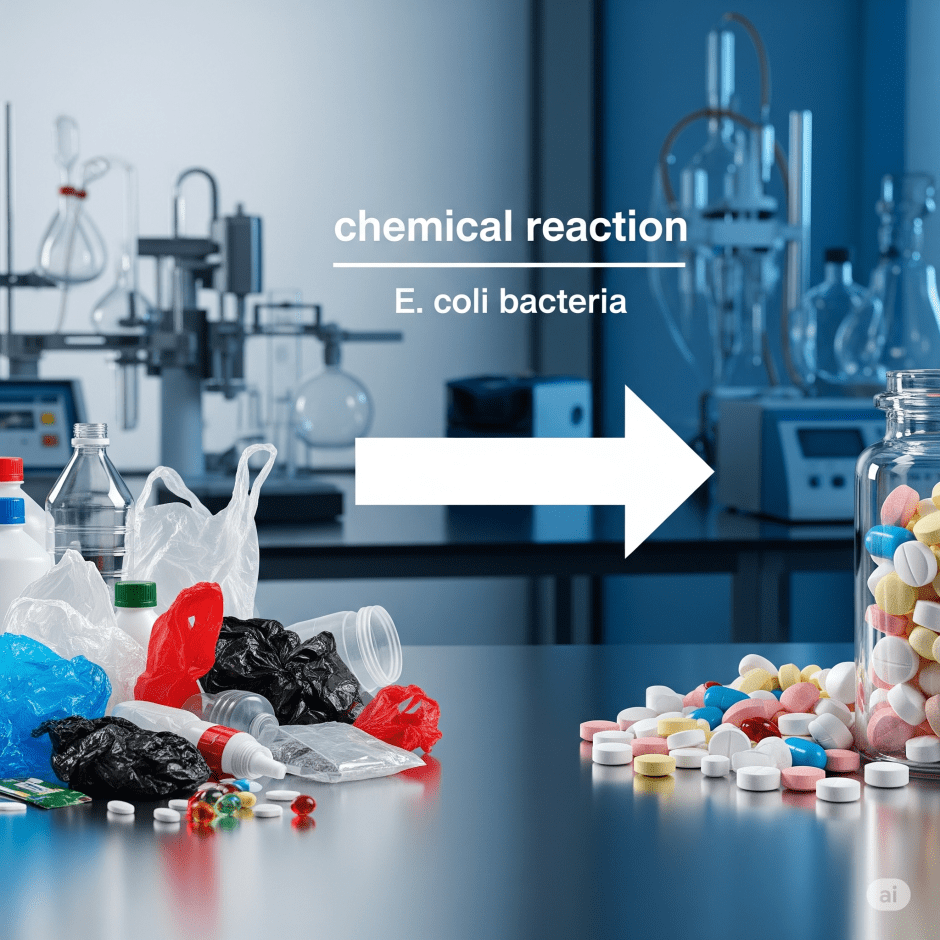

Betanin is a red colorant that can be extracted from red beetroots. Extracting a pigment from its natural source can be a wasteful and inefficient process given how little pigment is obtained as compared to the resources put into cultivating the crop. The authors of this study offer a more sustainable source of betanin. They engineered Yarrowia lipolytica, a yeast which is amenable to industrial fermentation. (Read more about the uses of yeast to improve human food and beverages)

The authors studied the biosynthesis pathway of betanin and screened for catalytically favorable enzyme variants in yeasts to select the best-performing enzymes’ genes (maximising efficiency of desired product generated from the substrate)and introduce those genes in a target organism. Think of it this way, the biosynthesis pathway is a multistory building where each floor is made of different material (analogous to different enzymes). Each time before making the floor, you would want to test out different options for materials before choosing the best option for that floor.

That’s exactly what the scientists did. Their engineering worked! The culture of the yeast was orange in color. Turns out they had made the unstable cousin of betanin, betanidin. To convert betanidin to betanin, they added another enzyme after screening again. Interestingly this led to the yeast secreting betanin (60%) and it’s identical twin isobetanin. Identical twins, as the name suggests, look the same. Here too that was the case, so the authors decided to treat isobetanin as the same for their purposes of food colorant (they even checked beets and saw that beetroot also had 45% isobetanin).

Before moving on to what the authors did next, let’s consider a situation. You are sitting in a hot room. What do you? You turn on the fan and feel cooler. What do you do then? You turn off the fan. This is a feedback loop and can be found in our cells too. These feedback loops exist to inform the cell when to stop producing something in excess. However, in this case, we need the pigment to be produced in excess. So, the authors engineered a feedback-insensitive gene to improve the production of the red dye.

Going back to our multi-story building, after construction sandpapering and painting steps are undertaken to beautify the project. The authors took similar steps to remove side product formation to improve betanin production.

They then tested the engineered yeast in a small bioreactor to assess the commercial feasibility and environmental sustainability of betanin production. They were able to generate 1197 mg of the red dye in 48 hours. Whereas, 100g of beets, cultivated for 50 days only produce 200mg of red dye. Doesn’t take complicated mathematical analysis to see their astounding success! However, the authors offer extensive calculations on how their method is far better for the environment on multiple scales as well as an economically viable strategy. After all, any food-grade product needs to be both economically and environmentally viable for the successful commercialisation of the product in today’s day and age.

Link to the original post: Thomsen, P.T., Meramo, S., Ninivaggi, L. et al. Beet red food colourant can be produced more sustainably with engineered Yarrowia lipolytica. Nat Microbiol 8, 2290–2303 (2023). https://doi.org/10.1038/s41564-023-01517-5

Featured image: Photo by Geraud pfeiffer from Pexels: https://www.pexels.com/photo/beetroot-puree-on-plates-on-table-6607319/

Other Microbites Articles on Uses of Yeast:

https://micro-bites.org/2021/11/10/improving-wine-with-a-cocktail-of-micro-organisms/

https://micro-bites.org/2021/03/22/sourdough-bread/