Breaking down the microbiology world one bite at a time

The microbes creating useful chemicals out of thin air

A group of researchers from the United Kingdom, Germany and the United States have engineered the bacterium Cupriavidus necator H16 to potentially help capture CO2 from the atmosphere – all while turning it into mevalonate, an essential precursor for molecules like cholesterol, steroids and cell wall components, and therefore a useful chemical for the production of pharmaceuticals.

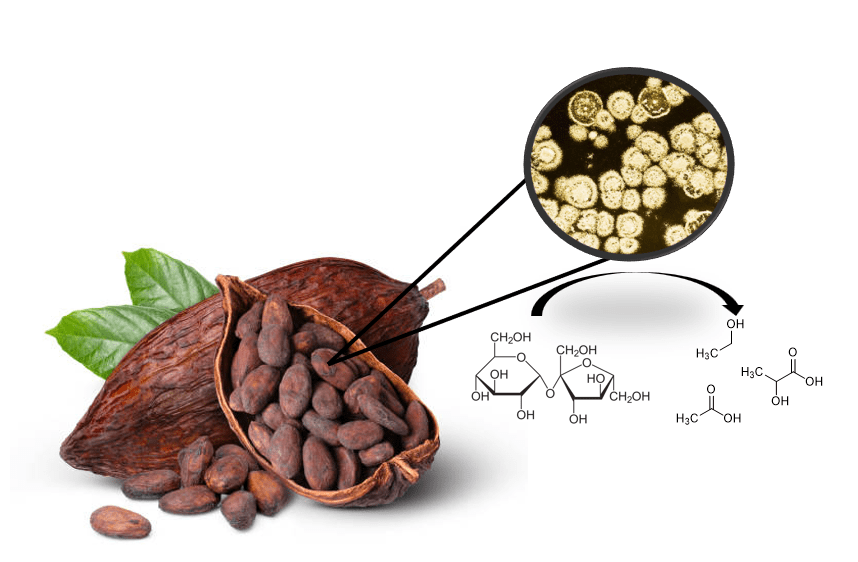

Microscopic factories running on sugar

In the biotechnology industry, microbes are used as tiny factories to produce all sorts of chemicals, from antibiotics to biofuels. Most often, the food they need is a type of sugar, like glucose or sucrose. The microbes use these sugars as a source of carbon, which they need both to grow and to supply us with the chemicals that we program them to make. But what if there was a carbon source that is much easier to get, one that is literally everywhere around us?

Greenhouse gases as the Earth’s blanket

The main driver of climate change is the increased amount of greenhouse gases, like CO2 and methane, in the atmosphere. They act as the Earth’s blanket, trapping warmth underneath it and increasing global temperatures. To tackle the devastating effects of global warming on our planet, we can do two things: (a) decrease our emissions of these gases to make sure their concentrations in the atmosphere do not rise as quickly as they have so far, and (b) capture the gases that are already present in the atmosphere. An international group of researchers propose a potential win-win situation: a microbe that is able to survive on CO2 as the sole carbon source, and uses it to create chemicals valuable for the production of pharmaceuticals. This way, CO2 from the atmosphere is not only captured, but also turned into a useful product.

The forgetful bacterium that makes its own food

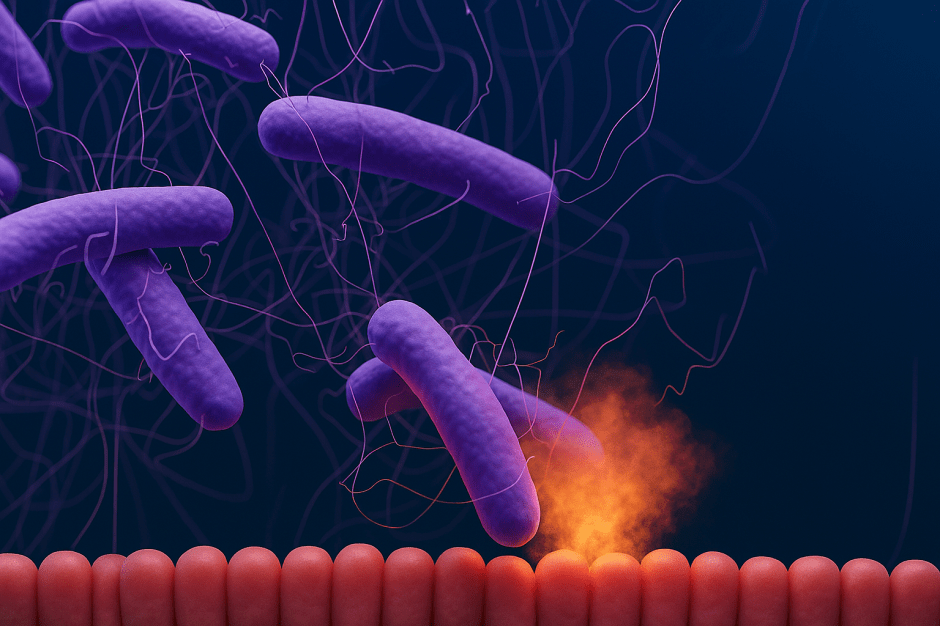

The microbe in question is Cupriavidus necator H16, a facultative chemolithoautotroph able to grow using only CO2 and H2 (hydrogen gas). Autotrophic organisms are ‘self-feeders’: they can essentially make their own food by synthesising organic compounds, like glucose, from CO2. The non-fussy character of C. necator H16 makes it very interesting for the biotechnology industry, but there is a catch: when told how to make a certain product, the bacterium is not great at remembering those instructions. In other words, when it is engineered with a plasmid containing the information about what product to make and how, it struggles with maintaining that plasmid. Until now, this forgetfulness made it tricky to use C. necator H16 as a microbial cell factory in the biotechnology industry. But Garavaglia et al. came up with a solution: using a method called plasmid addiction system.

Those with good memory survive

When teaching a bacterium to create a compound it does not make naturally, researchers often use horizontal gene transfer (HGT) to give the organism instructions. During HGT, a new piece of genetic information, usually in the form of a plasmid (a small circular piece of DNA) containing the necessary instructions, is introduced into the bacterium. Sometimes, microbes struggle with keeping the plasmid over time, and do not pass it on to future generations – they lose, or forget, the instructions, just like in the case of C. necator H16. In this study, the researchers gave the bacterium instructions on how to make mevalonate using CO2. To make sure that all the bacteria in their experiment had the plasmid and could produce mevalonate, they used the plasmid addiction system (PAS) method – as the name suggests, the bacterium became dependent on the plasmid to survive.

A plasmid you cannot live without

The simplest way to make sure a bacterium does not lose a plasmid is to make its life depend on it. There are different types of PAS; the one used by the researchers in this study is called ‘essential gene complementation’. In this method, the scientists first create a knockout strain of C. necator H16 by deleting a gene from its genome. In this case, that gene encodes RubisCO – an enzyme that the microbe absolutely needs to be able to survive on CO2. Without this gene, the knockout strain will die – unless, of course, it is given the exact same RubisCO-encoding gene on a plasmid! If this is the plasmid that also contains instructions on how to make mevalonate, the bacterium will always ‘remember’ those instructions – because if it loses the plasmid, it will no longer be able to make the essential RubisCO and die.

Simplified diagram of engineered C. necator H16. Image source: adapted from Garavaglia et al., 2024. Illustrated by Michaela Krupová using Krita 5.0.6.

A win-win situation

The researchers report that in this study, they were able to produce the highest amount of a C6 compound (large organic molecule made up of six carbon atoms, like mevalonate) from a C1 molecule (containing only one carbon atom, like CO2) than any study has done before. Normally, mevalonate is produced in the industry from organic carbon sources, like glucose. Using CO2 instead would make its production, and that of many other compounds, cheaper and more sustainable, while at the same time reducing the amount of the unwanted greenhouse gas in our atmosphere.

Link to the original post: Garavaglia, M., McGregor, C., Reddy Bommareddy, R., Irorere, V., Arenas, C., Robazza, A., Minton, N. P., Kovacs, K. Stable Platform for Mevalonate Bioproduction from CO2. ACS Sustainable Chemistry & Engineering 2024 12 (36), 13486-13499. doi: 10.1021/acssuschemeng.4c03561

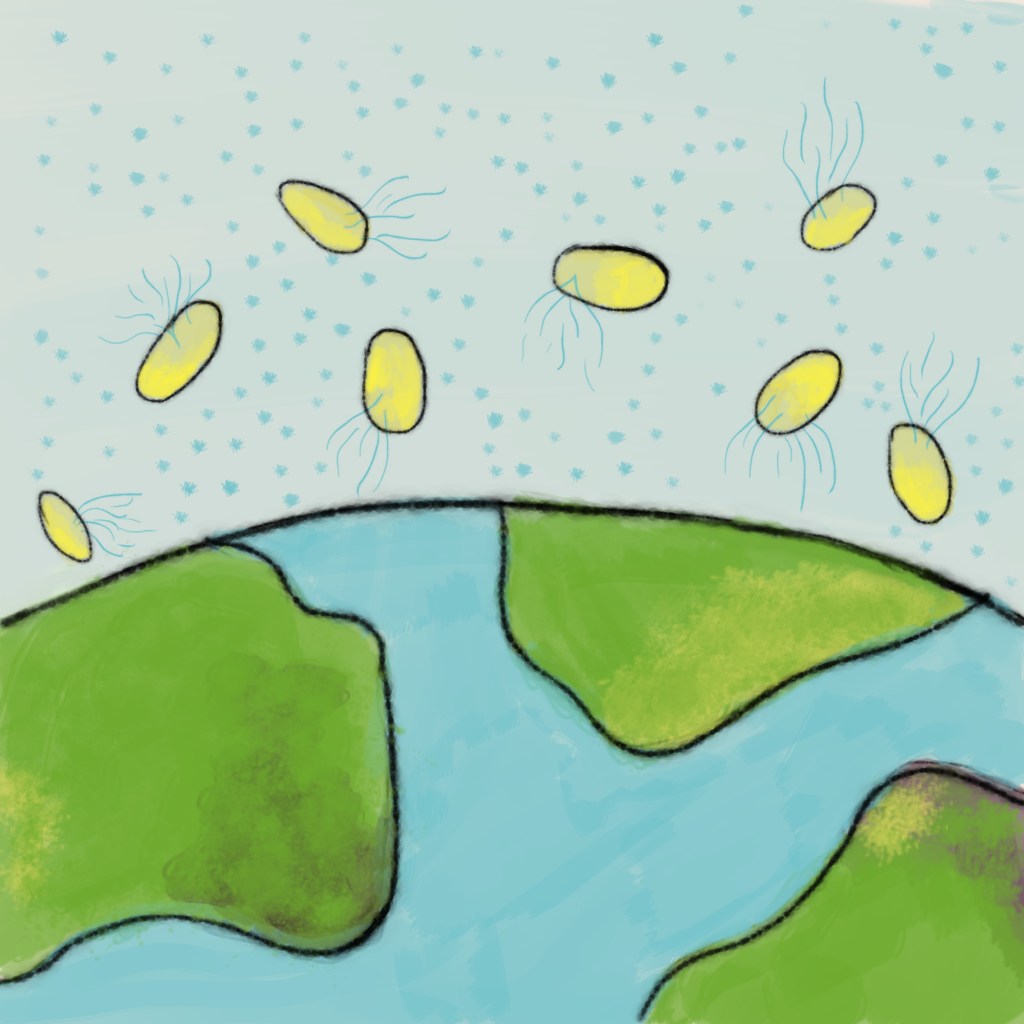

Featured image: Illustrated by the author using Krita 5.0.6